Platinum Lifetime

- Messages

- 2,646

- Reactions

- 5,091

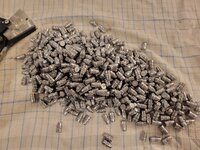

I will be shooting 10mm today.I'll be making 10mm today after I get back from visiting the vampires.

I have 2 doctor appointments tomorrow and I will be in shock if they don't try to drain some blood out of me.