Bronze Vendor

Gold Supporter

- Messages

- 64

- Reactions

- 153

A customer dropped off a gorgeous Ruger M77 chambered in .338 Win Mag and claimed it was having issues extracting. They suspected the extractor might need replacing, as it would not even extract an unfired case from the chamber. They also suspected there could be trouble with the chamber.

Bore scoping the chamber did reveal some rough areas around the throat, but nothing alarming. I decided to tackle the issue of unfired rounds not extracting first. The extractor looked like it had been polished at some point, but it was still grabbing cases with the bolt removed from the rifle. With the bolt installed, sure enough, a live round would not extract and would simply fall out under its own weight.

I marked up the rim of a case with some Sharpie and chambered it. After removal I checked where the Sharpie was rubbed off. It looked as if the extractor was not quite making it far enough to get over the rim of the case. I begun to suspect headspace.

The problem was, I did not have any gauges on hand for .338 Win Mag. I called PT&G and they did not have any on the shelf. In the interest of getting the customer a quick answer, I decided to make my own.

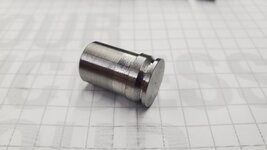

I looked up the SAAMI spec for the chamber dimensions. On these belted cartridges, the headspace is not contrlled by the shoulder. Rather, it is the dimension from the case head to the front of the belt. .338 Win Mag has a max headspace of .227". I drew up a quick sketch using dimensions from the chamber and the cartridge spec, and then fired up the lathe. Finished product measures .277" and change. What's a few tenths among friends?

Now was the moment of truth. And sure enough, the rifle swallows the gauge. Curious, I decided to make a slightly more field expedient gauge. I took an unfired cartridge and began building up layers of tape on the case head. I admittedly lost count after 5 layers. It was around 7 or 8 that the bolt finally had trouble closing. Each layer of tape is around .004" thick. The case I was using had a headspace measuring roughly .220. The math works out that the rifle has a headspace approximately .020" over spec.

I am still waiting on a response from the customer on where he'd like to go from here. My hope is that he approves turning the shoulder back on the original barrel and rechambering it. I would obviously order some "real" headspace gauges before doing so.

Standby.

Bore scoping the chamber did reveal some rough areas around the throat, but nothing alarming. I decided to tackle the issue of unfired rounds not extracting first. The extractor looked like it had been polished at some point, but it was still grabbing cases with the bolt removed from the rifle. With the bolt installed, sure enough, a live round would not extract and would simply fall out under its own weight.

I marked up the rim of a case with some Sharpie and chambered it. After removal I checked where the Sharpie was rubbed off. It looked as if the extractor was not quite making it far enough to get over the rim of the case. I begun to suspect headspace.

The problem was, I did not have any gauges on hand for .338 Win Mag. I called PT&G and they did not have any on the shelf. In the interest of getting the customer a quick answer, I decided to make my own.

I looked up the SAAMI spec for the chamber dimensions. On these belted cartridges, the headspace is not contrlled by the shoulder. Rather, it is the dimension from the case head to the front of the belt. .338 Win Mag has a max headspace of .227". I drew up a quick sketch using dimensions from the chamber and the cartridge spec, and then fired up the lathe. Finished product measures .277" and change. What's a few tenths among friends?

Now was the moment of truth. And sure enough, the rifle swallows the gauge. Curious, I decided to make a slightly more field expedient gauge. I took an unfired cartridge and began building up layers of tape on the case head. I admittedly lost count after 5 layers. It was around 7 or 8 that the bolt finally had trouble closing. Each layer of tape is around .004" thick. The case I was using had a headspace measuring roughly .220. The math works out that the rifle has a headspace approximately .020" over spec.

I am still waiting on a response from the customer on where he'd like to go from here. My hope is that he approves turning the shoulder back on the original barrel and rechambering it. I would obviously order some "real" headspace gauges before doing so.

Standby.